At Re:Build Optimation, we help manufacturers move from concept to reliable, scalable production. Whether developing pilot systems, modernizing existing processes, or expanding to full-scale operations, our team delivers engineered solutions that improve performance, ensure compliance, and minimize risk. From design and fabrication to installation and startup, every system is built for safety, quality, and long-term reliability.

Bringing new processes to production is complex. Timelines are tight, standards are demanding, and downtime is costly. Our modular, skid-based systems help manufacturers move from pilot to production with speed and confidence. Designed for rapid deployment and long-term reliability, they minimize installation time, reduce disruption, and ensure compliance every step of the way

When your plant needs to modernize, expand, or integrate new systems, downtime and risk are top of mind. Re:Build Optimation helps manufacturers upgrade with confidence. Our engineering and consulting expertise ensures your systems work smarter, run reliably, and stay compliant, extending the life of your assets while positioning your facility for future growth.

When you have installations, upgrades, maintenance, or repairs critical to your operations, you want skilled professionals who know your plant and deliver work you can trust. Re:Build Optimation provides certified tradespeople with the experience to complete every job safely, efficiently, and to the highest standards. From emergency repairs to large-scale installations, we keep your systems running smoothly and downtime to a minimum.

Your ability to deliver high-quality films, foils, and flexible materials relies on consistent, flawless production. Re:Build Optimation equips manufacturers to improve yield, reduce defects, and boost throughput with roll‑to‑roll systems engineered for reliable performance. Leveraging decades of expertise and our dedicated Media Conveyance Facility (MCF), we help you produce more, waste less, and exceed demanding customer and industry standards.

Handling powders and bulk solids requires solutions that deliver consistent results and meet rigorous industry standards. Re:Build Optimation helps manufacturers maximize efficiency, minimize risks, and simplify compliance with customized systems for conveying, blending, drying, and packaging. Our engineering approach focuses on delivering systems that operate safely, reliably, and within required performance parameters throughout the entire production process.

Re:Build Optimation supports clients operating in some of the most demanding industrial environments. Our engineering, fabrication, and field service teams deliver systems that meet exacting performance, safety, and compliance standards across every market we serve.

Scaling complex chemical manufacturing processes safely and efficiently, reducing risk while improving reliability and throughput.

Enabling faster, compliant scale-up of pharmaceutical and biotech operations, ensuring product integrity, process validation, and production readiness.

Supporting innovators in hydrogen and advanced energy with proven systems that accelerate commercialization and ensure safe, reliable performance.

Helping glass and ceramics producers improve precision, quality, and efficiency in high-temperature manufacturing environments.

Delivering sanitary systems that help food and beverage producers increase output, enhance safety, and maintain consistent product quality.

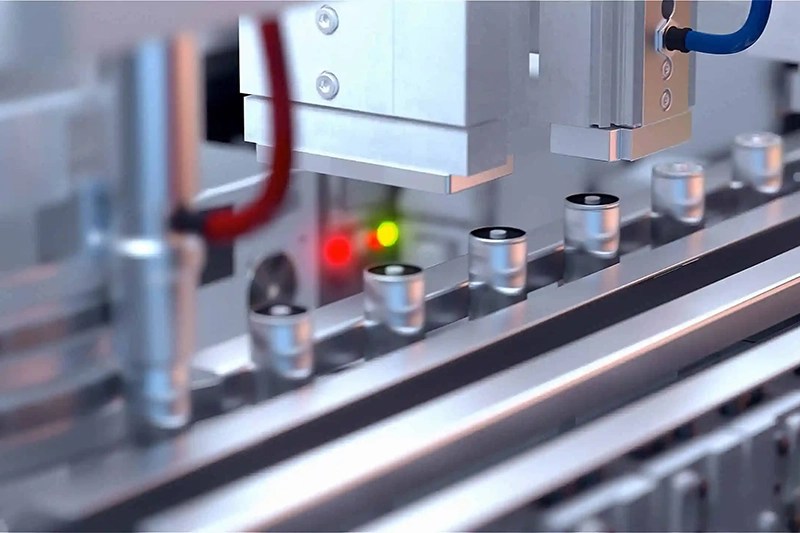

Working with manufacturers to modernize operations, automate processes, and achieve higher productivity with reduced downtime and cost.

Tell us about your process or project, and we’ll connect you with the right expert at Re:Build Optimation.