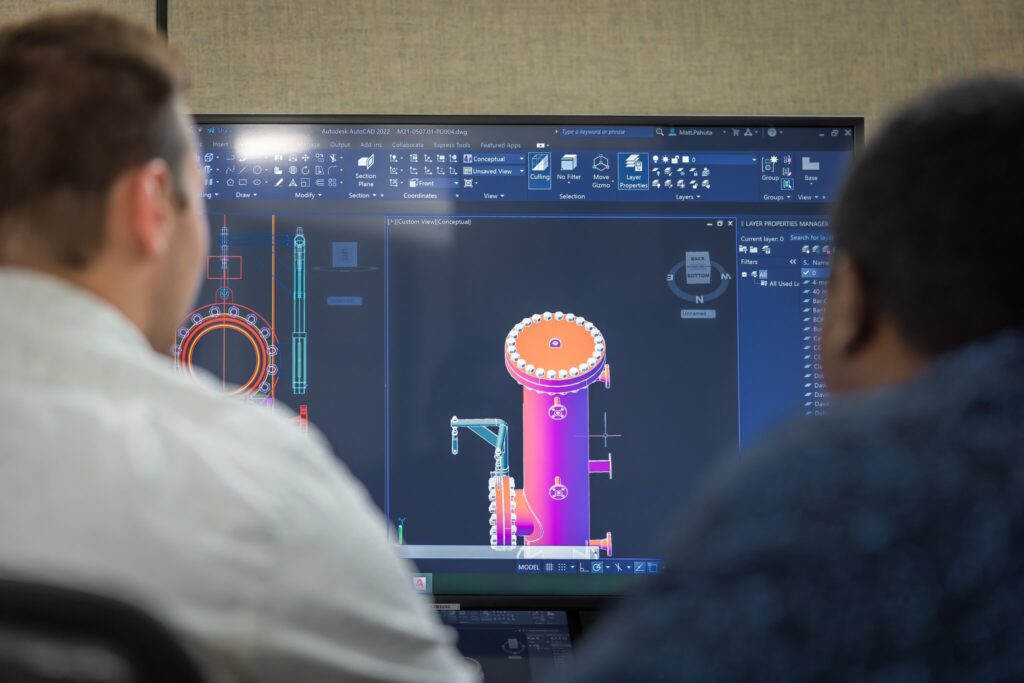

Outdated systems, disconnected processes, and evolving requirements can limit performance, but so can facilities that were never designed for new products or higher throughput. Re:Build Optimation provides upgrades, integration, and consulting services that modernize existing equipment, connect systems, and enable new production capabilities. Our work supports capacity expansion, product changeovers, and data-driven operations, helping manufacturers improve reliability, bring new processes online, and scale with confidence.

We help manufacturers modernize critical systems in ways that improve performance, reduce risk, and support long-term operational growth.

Upgrade legacy controls with modern control platforms and automation logic to improve reliability, precision, and safety.

Connect equipment and utilities for seamless plant-wide performance.

Ensure systems meet evolving regulatory requirements and reduce operational risk.

Redesign and reconfigure existing systems to extend equipment life and increase efficiency.

Unlock real-time insights to drive smarter, higher-value operations.

Our upgrades, integration, and consulting services support clients who are:

With more than 40 years of experience and 20,000+ projects delivered, Re:Build Optimation brings unmatched knowledge of system upgrades and plant-wide integration. We combine engineering expertise with skilled trades to deliver safe, reliable results.

From consulting and design through installation and startup, we manage the entire lifecycle of your upgrade or integration. Our teams provide full accountability, ensuring every project is completed safely, on schedule, and to the highest standards.

Our integration work does more than connect systems. By implementing advanced controls and analytics, we help manufacturers unlock actionable insights that improve process performance, compliance, and long-term value.

Tell us about your process or project, and we will connect you with the right expert at Re:Build Optimation.