Food & Beverage

A client in the food industry needed to replace a legacy ABB MOD300 distributed control system without stopping production for longer than 12 days.

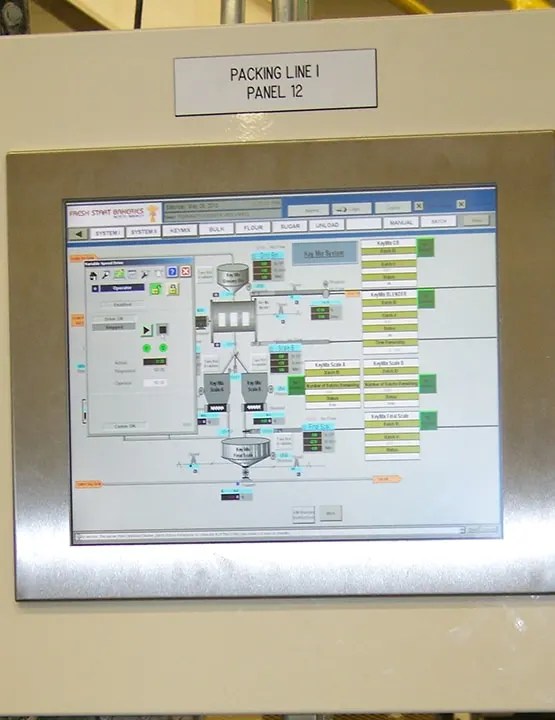

Re:Build Optimation designed a ControlLogix PlantPAx automation system to provide plant wide functionality. A functional specification and sample operator screens were developed in cooperation with the production team. Panels were built in a staging area for operators to be trained using a simulated model of their production environment. Concurrently, Re:Build Optimation’s electrical installation team installed new conduit and pre-bundled electrical cables in advance of the shutdown window. Once the entire installation team was comfortable with the operation of the system in simulation mode, a round-the-clock dismantlement and install effort including over 35 electricians commenced.

Re:Build Optimation completed the project on-time and on-budget. The replacement also increased production rate by 5%, more than justifying the cost of the project. The new system allowed faster response in changing over jobs and running campaigns.

Let’s talk about your unique challenges and how Re:Build Optimation can help you.

All rights reserved Re:Build Manufacturing – Optimation ©2025