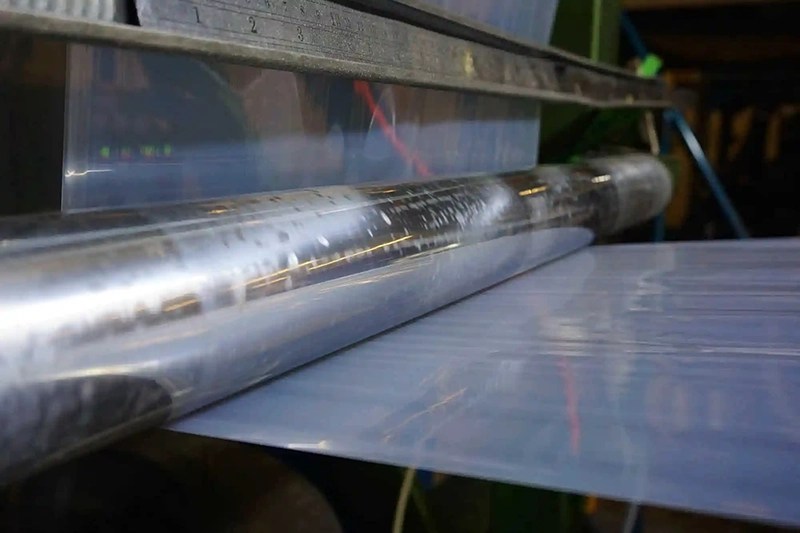

Moving a novel material from the lab onto a continuous substrate is one of the hardest challenges in advanced manufacturing. Re:Build Optimation delivers roll-to-roll coating and processing systems that give manufacturers the control needed to deposit, dry, and handle advanced materials consistently at scale. Drawing on decades of coating and conveyance experience, a database of over 1,500 web materials, and proprietary predictive models, our team designs systems that stabilize the web, control coating behavior, and reduce variability across the process. The result is reliable coating performance, improved yield, and confidence when transitioning from pilot to production.

Our roll-to-roll capabilities give manufacturers the control, consistency, and throughput needed to advance material performance and move from development to production more efficiently.

Tailored roll-to-roll platforms engineered to boost quality, throughput, and profitability.

Modernize legacy systems with advanced controls and optimized web handling.

Precision alignment, tension control, and wrinkle reduction to improve yield.

Integrated systems for high-performance material processing.

Real-time defect detection and analytics to ensure every product meets your highest quality targets.

Real-time defect detection and analytics to ensure every product meets your highest quality targets.

Our roll-to-roll solutions are trusted for:

When precision, consistency, and scalable production are essential, Re:Build Optimation delivers engineered coating and web-handling systems that support everything from benchtop development to full-scale roll-to-roll manufacturing. By integrating trusted vendor technologies with in-house engineering expertise, we help manufacturers accelerate process development, improve product quality, and move efficiently from prototype to production.

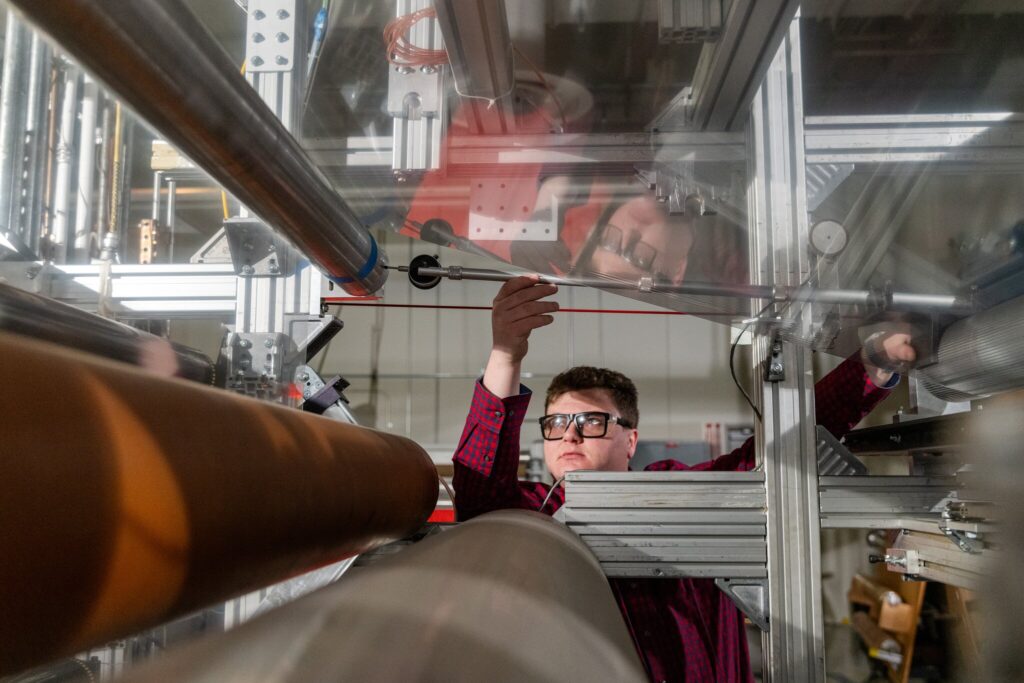

Building reliable roll-to-roll systems requires more than equipment, it demands a deep understanding of web mechanics, material behavior, and process interactions. Re:Build Optimation’s Web Handling Fundamentals workshop provides hands-on training grounded in decades of real-world engineering experience. The program covers essential web handling principles such as tension control, traction, wrinkling, splicing, winding, and process stability to support reliable, high-performance roll-to-roll systems.

We offer custom tramming rods and hand-held alignment kits available for order online, specifically designed for roller alignment and web handling equipment setup. Whether you’re aligning rollers, calibrating web paths, or setting up new machinery, our tools deliver the accuracy, repeatability, and efficiency you need.

Looking to solve complex web handling challenges or improve your roll-to-roll processes? Download our free library of technical white papers developed by Re:Build Optimation’s engineering experts to gain practical insights backed by real-world testing and analysis. Topics include fluid-structure interaction in thin webs, web-to-roller traction measurement, splice performance modeling, and more.

Decades of expertise means you get roll‑to‑roll systems that perform, no matter how complex the material or application. Clients trust us to solve tough production challenges and deliver reliable, scalable solutions.

End‑to‑end accountability, from initial concept to full production. Our integration of engineering, fabrication, and installation minimizes risk, speeds delivery, and ensures safe, repeatable results for your operation.

Our exclusive Media Conveyance Facility (MCF) lets us develop, test, and refine processes in-house, giving you faster innovation cycles and reduced risk when launching new products.

Tell us about your process or project, and we will connect you with the right expert at Re:Build Optimation.