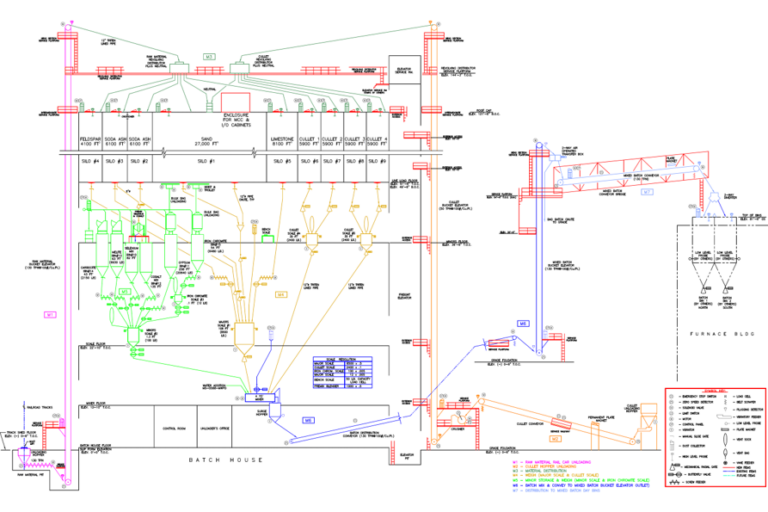

Batch House Equipment Modernization and Reliability Upgrade

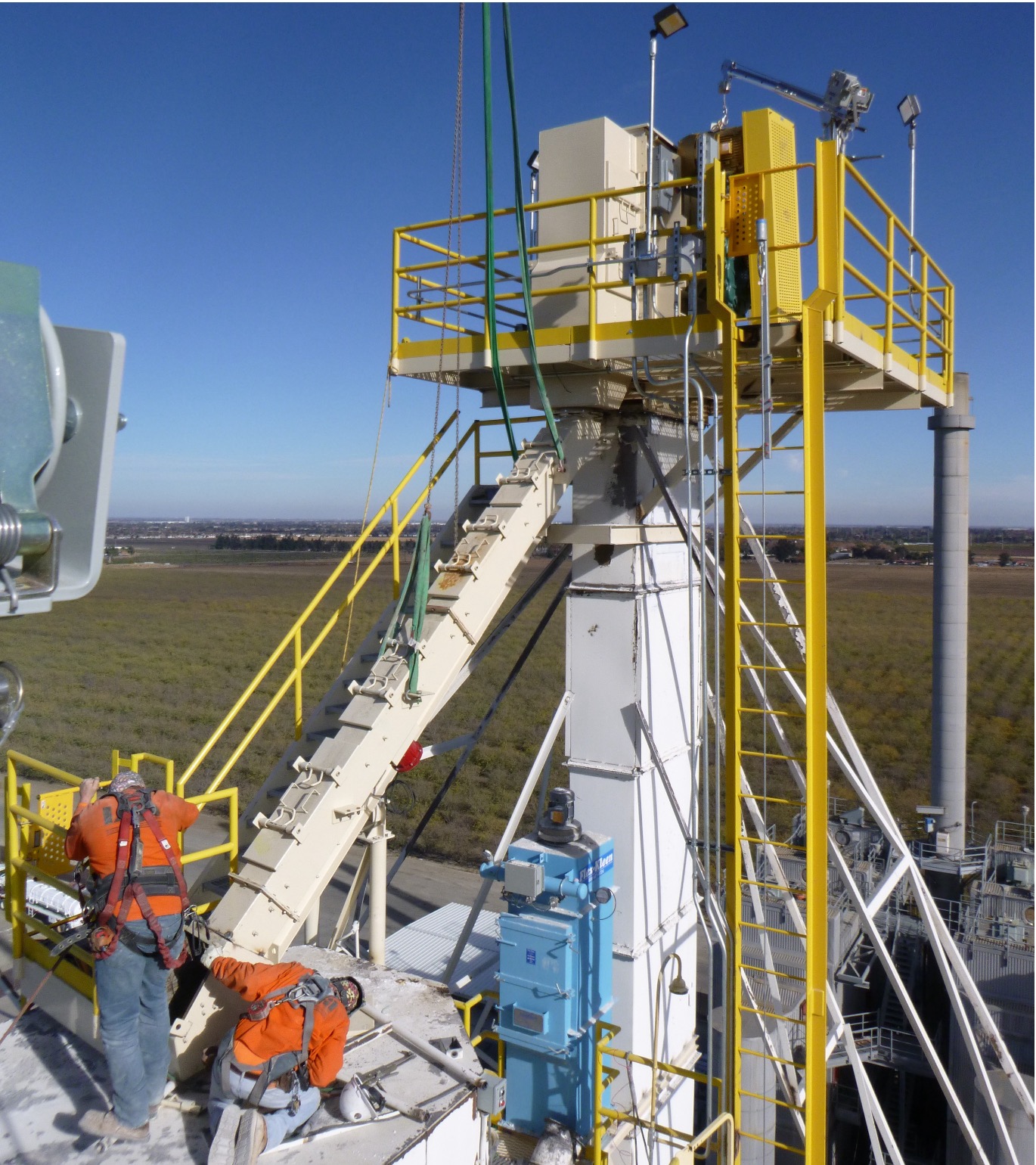

A legacy glass manufacturing plant faced chronic material loss, unplanned downtime, and rising maintenance costs due to aging batch house equipment operating well beyond its intended service life. Re:Build Optimation partnered with the plant team to assess the full batch operation and execute a phased modernization program aligned with production schedules and ROI priorities. The upgrades reduced waste, improved equipment reliability, and stabilized batch house performance while maintaining production continuity.