3 Ways to Measure the Value of Automation and Process Optimization

Reading an industry insight report recently, I recognized a condition that plagues many companies operating in today’s manufacturing markets: Change, Complexity, and Costs are so dynamic in ways and at speeds previously unequaled. How can our clients keep up with such challenging factors while achieving their goals and maintaining their advantages? How about exceeding those same goals and increasing their differentiating values?

Change Management for Controls Systems with Git

It is difficult to search software titles for very long without coming across something being sourced by a Git server (such as GitHub). As the default workflow for over 10 million software developers, coupled with the recent announcement that Google Code is being retired, there seems to be every reason to believe that Git is here to stay. How can those of us writing software for controls systems take advantage of this tool in our everyday work flow?

Apprenticeships: A long history and a bright future

November 11-17, 2019 is National Apprenticeship Week. National Apprenticeship Week was established four years ago by the US Department of Labor, and we’re glad to see more formal recognition of starting careers in the skilled trades. Re:Build Optimation has a strong apprenticeship program that was established twelve years ago and accredited by the New York State Department of Labor. While we may have been ahead of the curve in the recent drive to promote skilled trades, apprenticeships have been around for a very long time.

Nuclear Work Model: Training, Technical Procedures and Supervision

Health, Safety, and Environmental processes directly impact every aspect of an engineering and construction project. We understand this at Re:Build Optimation, which is why we have worked hard to develop a total approach to HSE challenges. Our HSE process is integral to our operations whether we are moving a manufacturing line from one plant to another, designing and fabricating a new line from client specifications, or providing additional multi-engineering and skilled trades services. The reason behind this is clear: when an organization integrates HSE programs into everyday roles and responsibilities, you get improved – bottom up/top down performance. What is already known and proven is that HSE performance is measurable both qualitatively and quantitatively. Lower incident and injury rates ultimately mean lower employee turnover, higher productivity, and lower overhead costs. This translates into completion of a project on time, on budget, and without incident.

The World is Flat & the Demise of the Global Supply Chain

In 1492 nearly everyone thought that the world was flat. Ships who ventured too close to the edge of the earth would fall in an abyss to their death or be eaten by large dragon like creatures. Columbus overcame all of that and the earth became round. That truth became foundation for a long time. But fifteen years ago Thomas Freidman published his book The World is Flat. It was the Financial Times Business Book of the Year in 2005 and sold millions of copies. It is because the gospel of global trade. In the book Friedman laid out the basis of offshoring, outsourcing and supply-chaining. Business owners read the book and accepted that the future was a global economy with both essential parts and essential products manufactured in all parts of the world, most dominantly in China. Six months ago, predictions for manufacturing trends during 2020 included more globalism with acceleration of Industry 4.0 technologies to make things faster, smarter and of higher quality. Predictions anticipated the growth of analytics, robotics and additive manufacturing. We couldn’t see, even then, that globalism would soon be dead. The flat world of Friedman would be disrupted even more quickly than the flat world of 1492 was disproved by Columbus.

What Are Hydrogen Separation Membranes?

If you’re interested in optimizing your hydrogen production operations with hydrogen separation membranes or related process technology, the experts at Re:Build Manufacturing LLC are here to help with imaginative ideas that drive efficiency, profits, and scalable growth. For the energy and power sector, we apply engineering and scientific principles to conceptualize and produce green energy systems that use hydrogen as well as methanol, biomass, solar, and wind power.

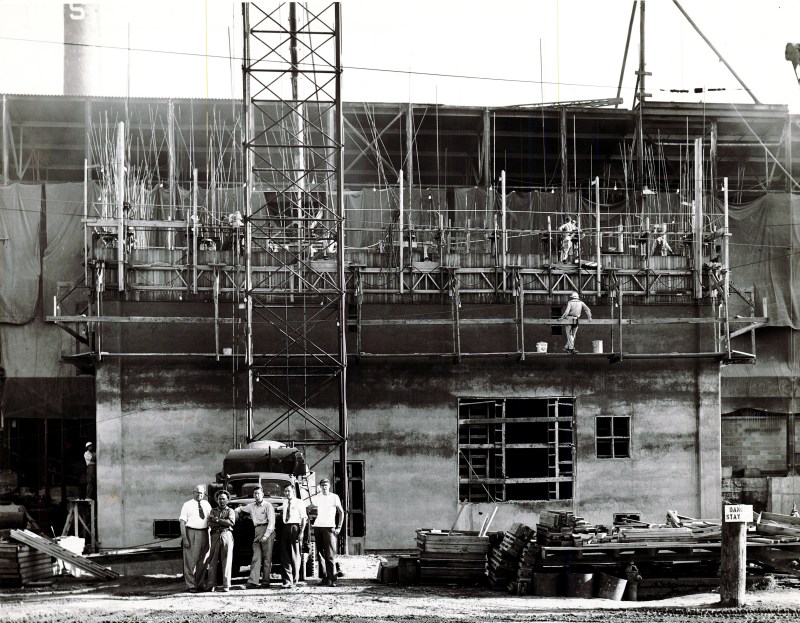

Glass Manufacturing in Rochester – Klug Systems by Optimation

Many people may not know that Rochester, NY is home to a company with significant contributions to the glass industry, Klug Systems by Optimation. Klug, the name it is most known by, can trace its roots back to the 1920s and 1930s when John Klug first founded the creatively named John L Klug Corporation. In the early years, Klug business was primarily an anthracite coal transportation company, but had transformed into a design and construction firm of coal silos by the 1930s. As the years progressed, John’s interest in the glass industry grew, leading him to investigate how to apply his coal storage expertise to glass manufacturing. Eventually, he would go on to modernize a small part of the glass industry.

5 Ways to Celebrate National Manufacturing Day

The first Friday of October every year has been designated as National Manufacturing Day. That day is set aside to proudly celebrate goods and services made in America. This year, more than ever, we are proud to celebrate American innovation. American manufacturers have led the world in technical development for the past two centuries and have enabled us to unlock new technologies that grow our economy.

The Impact of Rising Interest Rates on US Manufacturing

In February, 2009 the US economy hit a new low and in an effort to spur it along the Fed dropped the prime interest rates to a historic low of 3.25 percent. It stayed there for seven years and is just beginning to rise again, but slowly. Money has been cheap and abundant. In spite of this there has not been enough demand from the manufacturing sector to use all the available cash as investment capital to build new manufacturing infrastructure. Suddenly, in the spring of 2017 we have a new interest in increasing US manufacturing capacity and building new manufacturing plants. The initial investment will be made by large multinational well financed companies. Many of them have available cash reserves and are only looking for good ways to invest it. But the growth of these firms has a multifaceted ripple effect. Smaller firms, which are suppliers to these mega-firms, will get to grow with the economy as well. A rising tide raises all boats. Perhaps the question to ask is how rising interest rates will impact medium and small business as well as individual consumers.

Manufacturing Trends in 2024 – It’s All About Reshoring

Nearly twenty years ago Thomas Freidman published his book The World is Flat. It was the Financial Times Business Book of the Year in 2005 and sold millions of copies. It is because of the gospel of global trade. In the book, Friedman laid out the basis of offshoring, outsourcing, and supply-chaining. Business owners read the book and accepted that the future was a global economy with both essential parts and essential products manufactured in all parts of the world, most dominantly in China. Offshoring became the vogue and thousands of U.S. companies joined the siren song, closed U.S. plants, destroyed jobs, and nearly decimated the U.S. manufacturing base. That was then, but times have changed. Terms like onshoring, reshoring, nearshoring, new-shoring, and friend-shoring are now more in vogue. This change began to happen on a small scale, about a decade ago. But the alarm lights came on brightly during, and just after, the COVID-19 pandemic crystallized the view of supply chain limitations and risks. As we look at trends in manufacturing for 2024, we no longer see trends toward offshoring. We see quite the opposite. Five years ago, predictions for manufacturing trends during 2020 continue to include globalism with the acceleration of Industry 4.0 technologies to make things faster, smarter, and of higher quality. Predictions anticipated the growth of analytics, robotics, and additive manufacturing but not reshoring. We couldn’t see, even then, that globalism would soon be dying. The flat world of Friedman would be disrupted even more quickly than the flat world of 1492 was disproved by Columbus.