Process diagnostics and mechanical optimization for consistent, high-quality winding

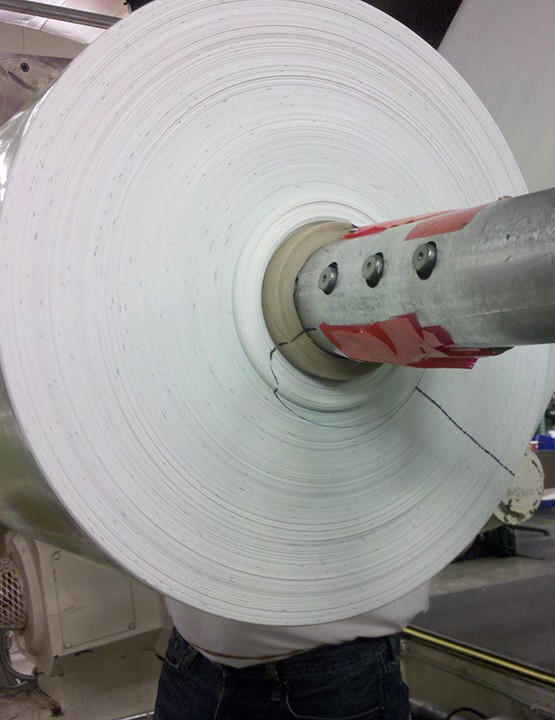

A manufacturer producing film and laminated products was experiencing roll defects described as roll blowouts on a REM slitter and rewinder. These defects occurred both during winding and after the rolls were removed, which created quality issues, increased scrap, and disrupted downstream processes.

The root cause of the instability was not clear. The client suspected either circumferential slip during winding or excessive tension and handling forces. They required specialized web handling expertise to confirm the failure mechanism, identify the contributing process variables, and implement corrective actions without major equipment replacement.

Re:Build Optimation conducted a detailed on-site evaluation of the winding process. The engagement included:

Re:Build Optimation delivered a comprehensive analysis of the client’s winding process along with a clear set of recommended process and mechanical adjustments. A custom winding model was also developed using characterization data from the client’s materials and equipment. The model predicts wound-in tension as a function of product properties and machine setpoints, which allows the client to standardize winding conditions for each product.

This combination of process diagnostics, practical recommendations, and modeling support enabled rapid improvements in winding performance.

The consulting engagement provided measurable improvements in roll stability and overall quality. Deliverables included:

These tools enable the client to transition to standardized, product-specific process conditions, which will help reduce winding variability and improve long-term process robustness.