TURNKEY SOLVENT COATER RETROFIT AND MODULAR TRAINING SYSTEM FOR ADVANCED MANUFACTURING WORKFORCE DEVELOPMENT

A technical education institute in the southeastern U.S. sought to build a hands-on training facility to address a growing skills gap in advanced manufacturing. Local employers in the film and plastics industries were struggling to hire qualified technicians, especially for coating and web conveyance roles.

The institute needed a fully functional training machine that mirrored real-world processes, could support multiple concurrent classes, and operated within a limited budget. Purchasing a new coater was not financially feasible, and off-the-shelf solutions lacked the technical fidelity and instructional flexibility required.

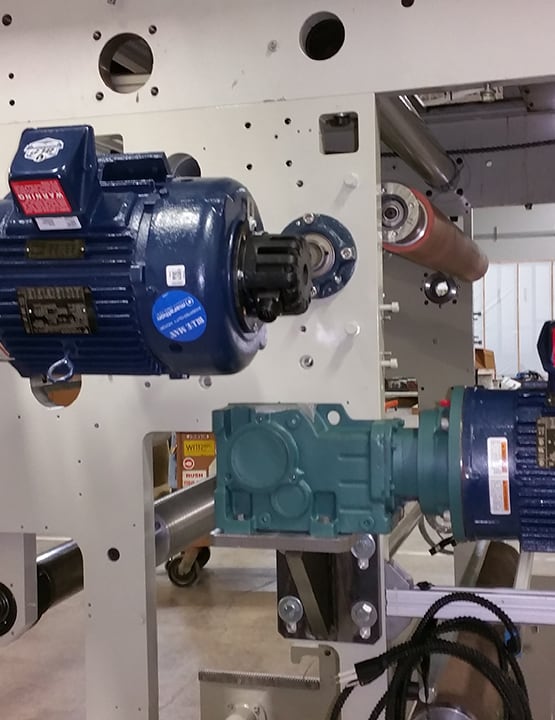

Re:Build Optimation was brought in to develop a creative and cost-effective solution. Rather than building a machine from scratch, the team sourced a used solvent coater from the UK and retrofitted it to support aqueous coating and modular training needs.

Key elements of the approach included:

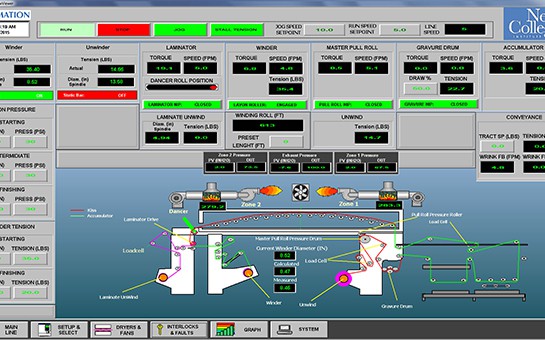

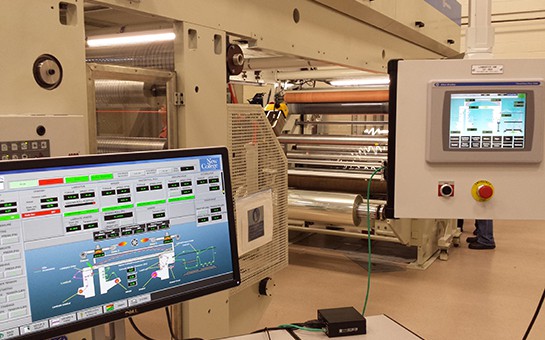

The retrofitted system was fully rebuilt for aqueous coating and optimized for technical instruction. Automation upgrades included:

The system was fabricated and tested in Re:Build Optimation’s Rochester, NY facility, then disassembled, shipped, and installed on-site. Final wiring and commissioning were completed in collaboration with local resources.

The retrofit project empowered the institute to deliver high-quality, hands-on training for local manufacturing roles. With continued use in educational programs and demand for additional system enhancements, the project stands as a model for budget-conscious, industry-aligned workforce development. Re:Build Optimation’s creativity and full-spectrum engineering support enabled the client to expand training capabilities while supporting local economic growth.

Let’s talk about your unique challenges and how Re:Build Optimation can help you.