TURNKEY SOLVENT RECOVERY AND SKID-BASED PRODUCTION EXPANSION FOR HIGH-GROWTH CHEMICAL MANUFACTURING

A specialty chemicals manufacturer experiencing rapid growth needed to expand production to meet rising demand for a proprietary insulation material. The facility operated 24/7 and required significant equipment and utility upgrades to boost throughput, recover process solvents, and maintain quality.

Because the manufacturing process involved a proprietary chemical formulation, the client required a partner capable of executing the project while maintaining strict confidentiality throughout design, installation, and startup.

Re:Build Optimation joined the project at the outset to assess the existing production setup, identify bottlenecks, and plan the system expansion. The team delivered a comprehensive solution that spanned process design, utility infrastructure, equipment installation, and control system integration.

Key workstreams included:

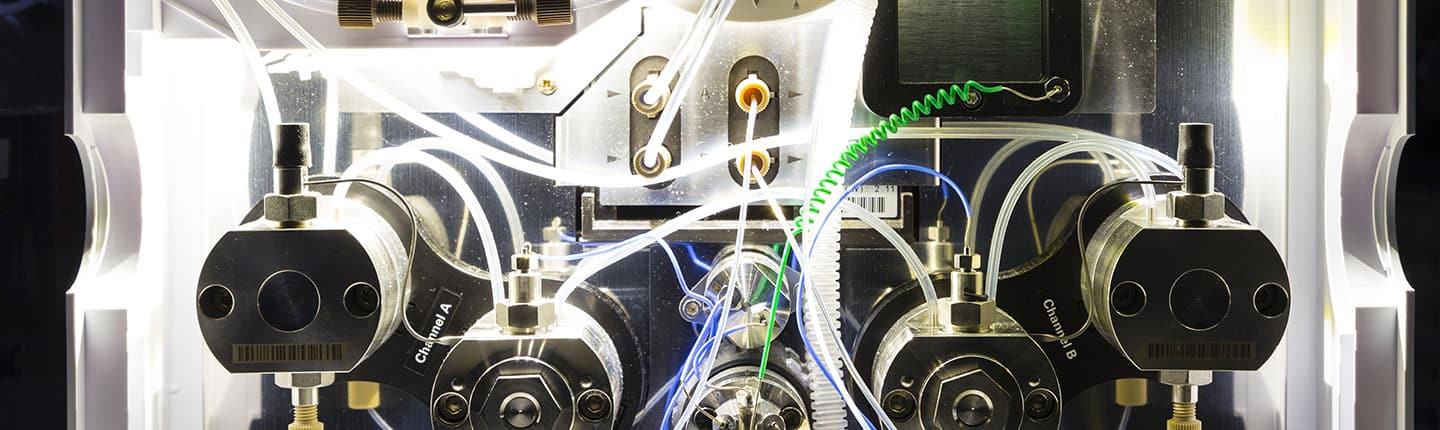

Re:Build Optimation delivered a skid-based expansion that enhanced production throughput and enabled greater solvent recovery efficiency without interrupting live operations.

Key components included:

All work was performed under confidentiality agreements to protect the client’s intellectual property and proprietary processing methods.

The expansion project significantly increased production capacity, reduced waste through solvent recovery, and improved operational control. With minimal disruption to ongoing manufacturing, Re:Build Optimation delivered a turnkey solution that enabled the client to scale safely and sustainably, while preserving the secrecy of their proprietary manufacturing process.

Let’s talk about your unique challenges and how Re:Build Optimation can help you.