Web Handling

A client manufacturing consumer products contacted Re:Build Optimation for web handling consulting. The client’s operation was experiencing significant quality issues and waste generation which was a threat to their production feasibility. The problem was described as the inability of their current equipment to convey sensitive web without inducing roller contact defects such as web digs and web scratches.

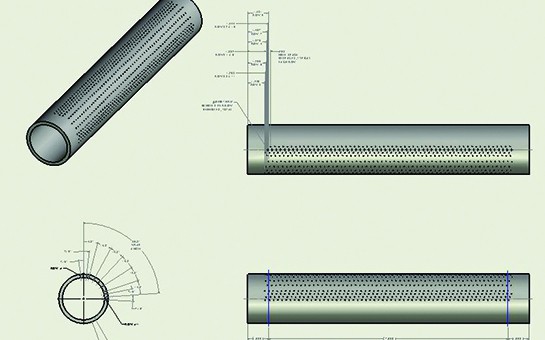

An Re:Build Optimation web handling consultant visited the client site to review equipment layout, observe process performance and defect issues, and work with the client to define the project scope, requirements and immediate action plans. The proposed process solution was to design a fluid bar conveyance system, which would replace the client’s submerged roller conveyance system. The new design would convey the sensitive web through the submerged web-path using fluid bars in place of rollers to avoid any web-to-rollers contact, which was creating subtle product defects. The fluid bar system design criteria was that the web floats evenly, within design clearance requirements, with no web to fluid bar contact, while maintaining lateral stability. Once the solution and proposed web path were determined, fluid bar models were used, taking into consideration existing pump pressure and flow rate specifications, to determine fluid bar diameter, hole size, and hole pattern for each fluid bar to meet the fly height objectives, while maximizing the no contact safety factor.

Utilizing the fluid bar model results, Re:Build Optimation supplied the client with detailed final drawings of each fluid bar in the web path. The fluid bars were then fabricated and retrofitted into the production equipment according to the drawings Re:Build Optimation provided. Production trials confirmed that the project was highly successful in achieving its objective of significantly decreasing product defects and associated waste. As a result of this success, the client requested the design of additional fluid bars for another section of the machine to further reduce defects.

Let’s talk about your unique challenges and how Re:Build Optimation can help you.