Test Systems for Life Sciences, Pharmaceutical and Medical Devices

Life Sciences and medical device manufacturers all over the world rely on test and measurement systems during the production process. These systems play a key role in improving product quality and overall productivity. At Re:Build Optimation, we have over 30 years of experience in providing quality test system integration to several industries, including life sciences, pharmaceutical and medical.

How to Know When to Say No to a Project

Sometimes, the right thing to do is say “no” and walk away.

When you are in business, especially in sales, the object is to win or sell as many jobs as you can, but sometimes it is better to turn down the opportunity if it is not a good match for your business or if the risk is too high.

We have talked about the importance of understanding the requirements for a project and how it is required to have a successful project. What happens when you understand the requirements and realize that the job is not the right fit for your company? Saying no to a large opportunity that is staring you in the face can be difficult, but it may be the best thing for your company.

When a project is not well defined with sound requirements it is very difficult to estimate the work. We’ve talked before about asking the right questions to define the job, doing preliminary engineering, etc.

Safety Lessons Learned the Hard Way

Just this past weekend a worker died in the Alberta oil sands region near Fort McMurray. We can take lessons from this tragedy and remind ourselves to study our practices to ensure that corners are not cut and best practices are employed to assure workplace safety. This blog post speaks to safety issues in general, as we have no relationship with the project, operators, or individuals in the Fort McMurray accident.

Industry 4.0 – What is the Return on Investment?

During the past decade, the Internet of Things has been steadily advancing and becoming a part of our lives. We get texts from our cars when the tire pressure is low or suggesting we should stop and buy another gallon of windshield washer fluid. We can turn on the oven or close the garage door at home from our office. These opportunities are supported by small amounts of data and provide simple solutions.

Asking the Right Questions During the Bid Process

Sometimes it is not what you say, but how you say it. In the engineering services world, we live by requirements (what you say – or write). Sometimes we create the requirements for or with our clients, and other times we write a proposal in response to the requirements and define a project to meet them.

3 Ways to Measure the Value of Automation and Process Optimization

Reading an industry insight report recently, I recognized a condition that plagues many companies operating in today’s manufacturing markets: Change, Complexity, and Costs are so dynamic in ways and at speeds previously unequaled. How can our clients keep up with such challenging factors while achieving their goals and maintaining their advantages? How about exceeding those same goals and increasing their differentiating values?

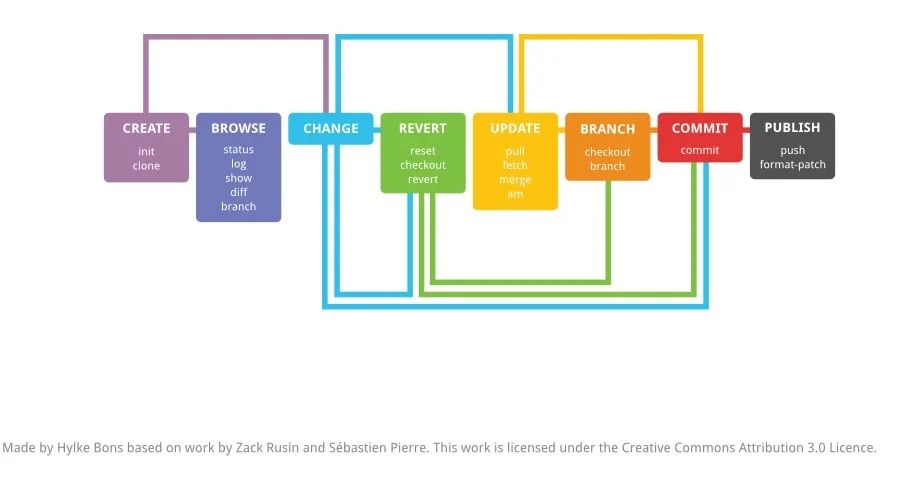

Change Management for Controls Systems with Git

It is difficult to search software titles for very long without coming across something being sourced by a Git server (such as GitHub). As the default workflow for over 10 million software developers, coupled with the recent announcement that Google Code is being retired, there seems to be every reason to believe that Git is here to stay. How can those of us writing software for controls systems take advantage of this tool in our everyday work flow?

Apprenticeships: A long history and a bright future

November 11-17, 2019 is National Apprenticeship Week. National Apprenticeship Week was established four years ago by the US Department of Labor, and we’re glad to see more formal recognition of starting careers in the skilled trades. Re:Build Optimation has a strong apprenticeship program that was established twelve years ago and accredited by the New York State Department of Labor. While we may have been ahead of the curve in the recent drive to promote skilled trades, apprenticeships have been around for a very long time.

Nuclear Work Model: Training, Technical Procedures and Supervision

Health, Safety, and Environmental processes directly impact every aspect of an engineering and construction project. We understand this at Re:Build Optimation, which is why we have worked hard to develop a total approach to HSE challenges. Our HSE process is integral to our operations whether we are moving a manufacturing line from one plant to another, designing and fabricating a new line from client specifications, or providing additional multi-engineering and skilled trades services. The reason behind this is clear: when an organization integrates HSE programs into everyday roles and responsibilities, you get improved – bottom up/top down performance. What is already known and proven is that HSE performance is measurable both qualitatively and quantitatively. Lower incident and injury rates ultimately mean lower employee turnover, higher productivity, and lower overhead costs. This translates into completion of a project on time, on budget, and without incident.

The World is Flat & the Demise of the Global Supply Chain

In 1492 nearly everyone thought that the world was flat. Ships who ventured too close to the edge of the earth would fall in an abyss to their death or be eaten by large dragon like creatures. Columbus overcame all of that and the earth became round. That truth became foundation for a long time. But fifteen years ago Thomas Freidman published his book The World is Flat. It was the Financial Times Business Book of the Year in 2005 and sold millions of copies. It is because the gospel of global trade. In the book Friedman laid out the basis of offshoring, outsourcing and supply-chaining. Business owners read the book and accepted that the future was a global economy with both essential parts and essential products manufactured in all parts of the world, most dominantly in China. Six months ago, predictions for manufacturing trends during 2020 included more globalism with acceleration of Industry 4.0 technologies to make things faster, smarter and of higher quality. Predictions anticipated the growth of analytics, robotics and additive manufacturing. We couldn’t see, even then, that globalism would soon be dead. The flat world of Friedman would be disrupted even more quickly than the flat world of 1492 was disproved by Columbus.