Web Handling Solutions Classes 2026

High-quality, custom engineered and manufactured systems for hydrogen generation, fuel cells, electrolyzers, reformers, end of line test, and dispensing.

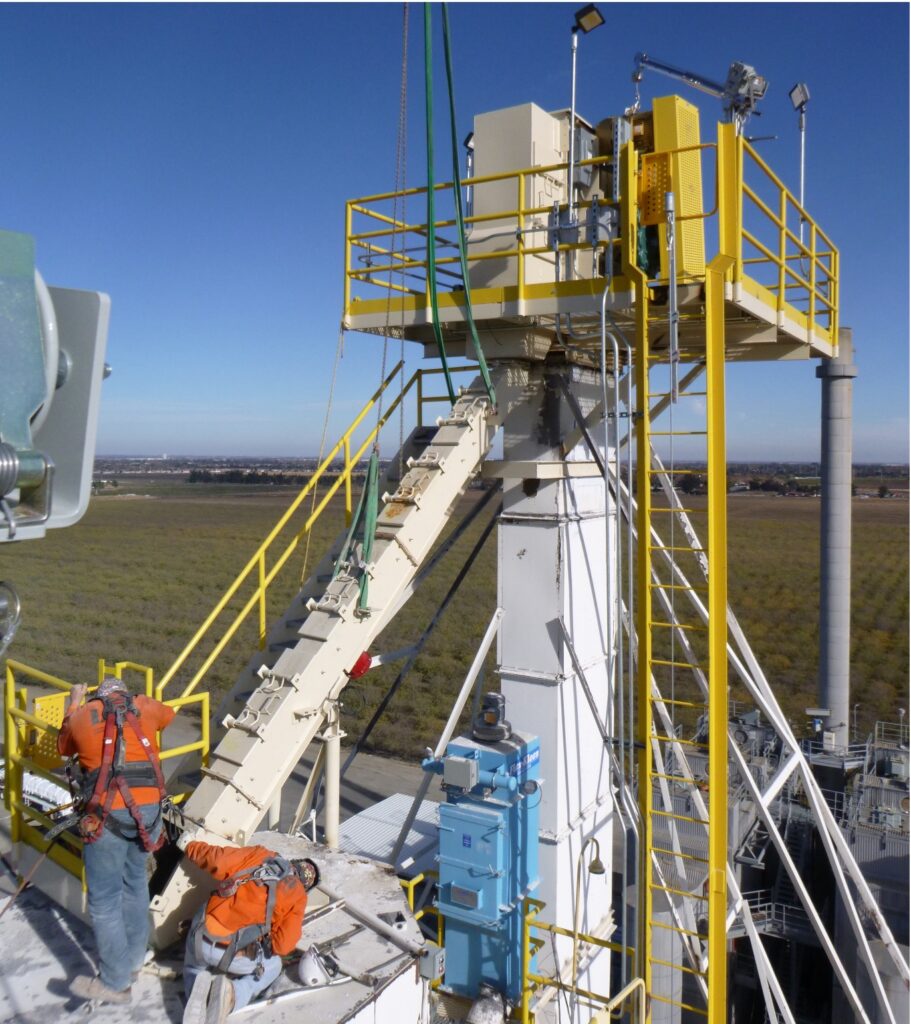

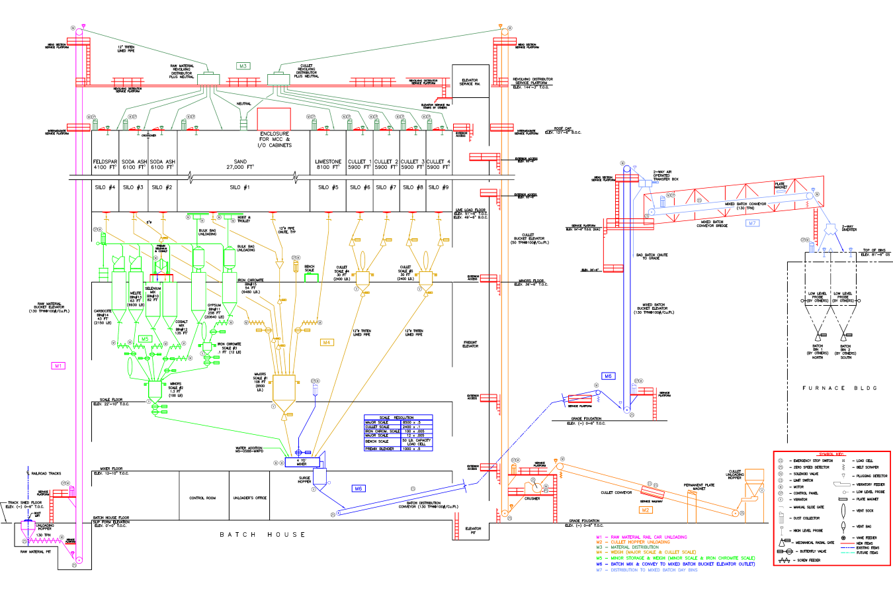

Batch House Equipment Modernization and Reliability Upgrade

A legacy glass manufacturing plant faced chronic material loss, unplanned downtime, and rising maintenance costs due to aging batch house equipment operating well beyond its intended service life. Re:Build Optimation partnered with the plant team to assess the full batch operation and execute a phased modernization program aligned with production schedules and ROI priorities. The upgrades reduced waste, improved equipment reliability, and stabilized batch house performance while maintaining production continuity.

Check Scale Modernization and Load Cell Upgrade

A glass manufacturer faced increasing material waste and unplanned downtime due to excessive wear and calibration drift in a critical batch house check scale system operating in an abrasive environment. Re:Build Optimation redesigned and modernized the system with more durable materials and upgraded load cell technology to improve accuracy and reliability while maintaining the existing footprint. The result was reduced waste, improved uptime, and a more reliable batching operation achieved through a targeted, cost-effective upgrade rather than full system replacement.

Colorant System Relocation and Integration

A glass manufacturer needed to add green glass production at an existing plant on a fixed timeline to support a product launch, but faced capital and schedule constraints and cross-contamination risks with its existing colorant systems. Re:Build Optimation repurposed and re-engineered a decommissioned colorant premix system, integrating it into the plant’s batch and control infrastructure to meet site-specific process and capacity requirements. The solution enabled a fast, capital-efficient launch of a new green glass production campaign while eliminating contamination risk and minimizing disruption to ongoing operations.

Batch House Audit Program and Maintenance Planning

Glass manufacturers often lack clear, data-backed insight into batch house condition, capacity, and maintenance risk, making it difficult to prioritize capital spending and secure funding for critical upgrades. Re:Build Optimation’s Batch House Audit Program combines on-site engineering evaluation with quantitative capacity and reliability analysis to create a clear, defensible roadmap for maintenance and capital improvement planning. The result is improved uptime, reduced waste, and prioritized, ROI-driven projects that enable informed capital allocation and long-term operational performance.

ARC Exchange Form

Let’s Stay In Touch

How to Go Fast and Still Manage Risk

In manufacturing, speed is often positioned as a critical competitive advantage. The quicker you can launch a new production line, scale up capacity, or bring a system online, the sooner you can meet customer demand, improve margins, and capture market share. But speed that compromises safety, quality, or regulatory compliance is not a smart tradeoff. It introduces risk that can derail an entire operation.

Automated Robotic System for Solid Oxide Fuel Cell Stacking

A manufacturer in the energy sector set out to transform one of its facilities from a research and development site into a scaled production environment for Solid Oxide Fuel Cells (SOFCs). To support this transition, the company needed to replace a limited in-house system with a fully automated, high-throughput machine capable of assembling SOFC stacks with speed and precision.

Determining Hazardous Area Classification Early

When companies scale from a benchtop lab to pilot-scale production, many focus on process efficiency, space requirements, and throughput. But too few stop to ask one essential question: Are we operating in an electrically hazardous environment? At Re:Build Optimation, we’ve seen how early hazardous area classification (HAC) assessments can fundamentally change the trajectory of a manufacturing project. When addressed early, HAC acts as a hidden risk reducer, informing design decisions, avoiding costly rework, and ensuring safety and compliance from the start. This blog breaks down why early HAC matters and how to approach it as a strategic investment rather than a compliance chore.

Start with AHJ Engagement

For startups working in specialty chemicals, advanced materials, or energy storage, the transition from lab to pilot plant presents many challenges. Among the most underestimated is regulatory compliance. At Re:Build Optimation, we have seen how early engagement with the Authority Having Jurisdiction (AHJ) often determines whether a project progresses smoothly or faces costly delays. This blog draws on real-world engineering experience and outlines a practical approach to the occupancy permitting process. Startups that take a proactive approach not only avoid rework and reclassification issues, but also gain credibility with regulators, community stakeholders, and potential investors.