Re:Build Optimation accelerates the growth of industrial manufacturers by delivering custom, modular process systems engineered for rapid deployment, compliance, and long-term reliability. We support companies developing new materials or scaling complex processes, helping them reach safe, efficient, production-ready performance. Our mission is to strengthen American manufacturing, empower our people, and create lasting value for the clients and communities we serve.

Re:Build Manufacturing was founded on the belief that American industry can be strengthened through engineering excellence, disciplined execution, and long-term investment in people and technology. The Re:Build Way, a set of 16 guiding principles, shapes how every Re:Build company operates and makes decisions.

At Re:Build Optimation, these principles guide how we manage projects, work with clients, and ensure safety, quality, and accountability. They reinforce our commitment to continuous improvement and help us deliver solutions that create lasting value for our clients and communities.

With more than 140,000 square feet of fabrication space across three Rochester, New York locations and over 20,000 projects delivered, Re:Build Optimation has the scale and capabilities to support projects of any size. By combining design, engineering, fabrication, and installation under one roof, we provide seamless execution and full accountability from concept through completion.

This 100,000-square-foot facility combines Re:Build Optimation’s full-service fabrication shop with advanced roll-to-roll media conveyance capabilities. Skilled tradespeople and engineers collaborate to build, test, and validate complex process systems for industries such as energy storage, specialty materials, and web handling.

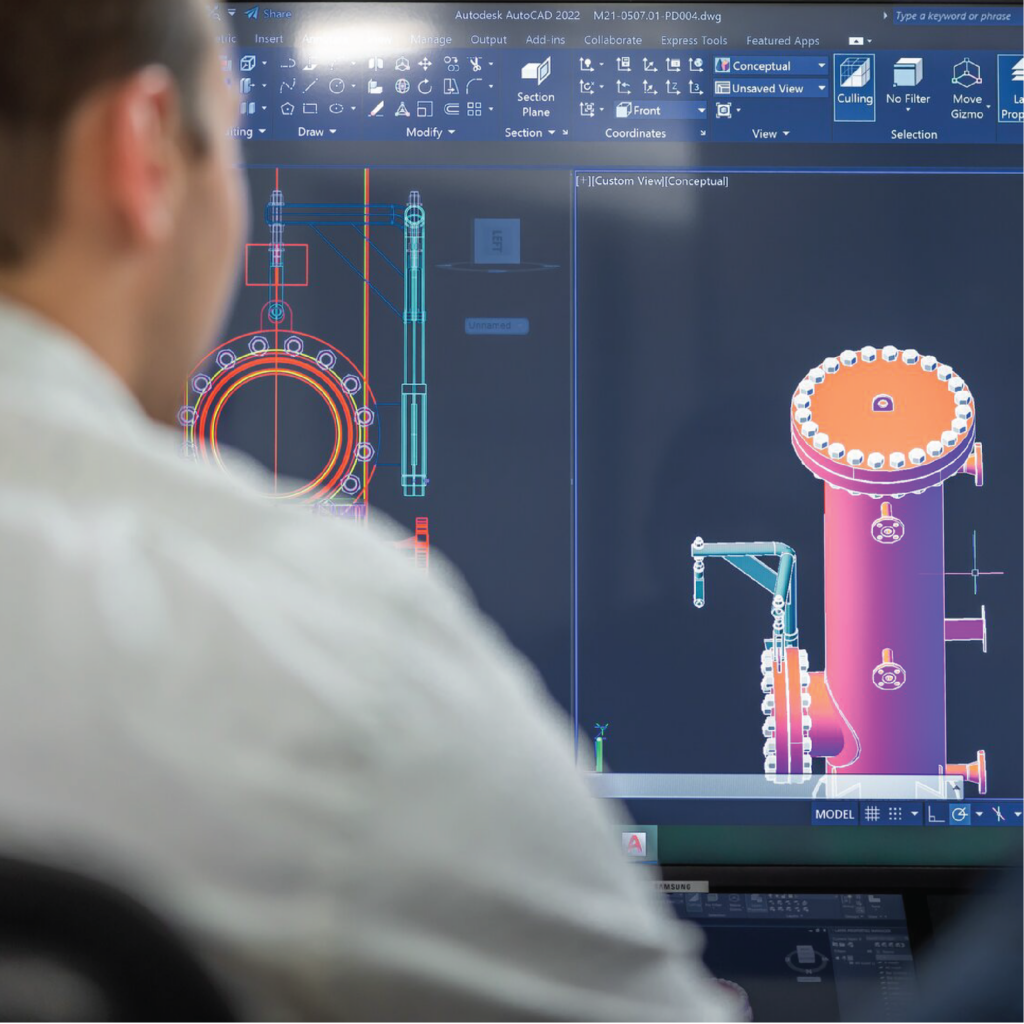

Home to Re:Build Optimation’s multidisciplinary engineering team, this collaborative space integrates mechanical, electrical, controls, and software design to deliver innovative, production-ready process systems.

Dedicated to mechanical assembly, controls integration, and panel fabrication, this 40,000-square-foot facility ensures seamless build, testing, and validation of automation and process equipment before delivery to clients.

Re:Build Optimation was founded in 1985 with a mission to provide integrated engineering and fabrication solutions for manufacturers. What began as a small team of engineers focused on process design and control systems has evolved into a nationwide provider of turnkey industrial solutions. Over four decades, Re:Build Optimation has grown through expansion, acquisitions, and innovation, building deep expertise in process systems, automation, and roll-to-roll manufacturing. Today, as part of Re:Build Manufacturing, Optimation continues to deliver end-to-end solutions that help clients design, build, and scale safe, efficient, and reliable production systems.

1985

Optimation was founded with a vision to deliver integrated engineering and fabrication solutions that help manufacturers design, build, and optimize complex process systems.

1992

Expanded operations with the opening of the Rush, NY Engineering Facility, strengthening design capabilities and enabling larger, more complex project delivery.

2002

Established deep expertise in batch and bulk material systems, building a reputation for solving demanding process challenges across multiple industries.

2004

Expanded skilled trades and engineering capabilities with the addition of highly experienced process engineering teams, strengthening support for chemical, pharmaceutical, and industrial markets.

2008

Expanded into a 100,000-square-foot facility that increased fabrication capacity and became home to the Media Conveyance Facility for web handling, roll-to-roll processing, and automation development.

2010

Added a new 40,000-square-foot facility for machine assembly and fabrication, increasing capacity and supporting more efficient system integration.

2021

Acquired by Re:Build Manufacturing, gaining access to advanced manufacturing resources, multidisciplinary engineering expertise, and a nationwide network of capabilities.

2025

Celebrating over 40 years of innovation and trusted partnerships, Re:Build Optimation continues to evolve as a leading provider of engineering and manufacturing solutions for industries across the U.S.

Our belief in the power of relationships, not only with our clients, but with our technology partners and in strategic alliances with other companies. Our clients in turn receive the benefits of these mutually beneficial relationships, experiencing a smooth installations and achieving their desired solution.

Governing our corporate processes is a quality management system registered to ISO 9001 since 1994. The pursuit of a repeatable and sustainable approach to business makes Re:Build Optimation unique as one of only a few firms that are recognized by both ISO 9001 and Control Systems Integrators Association (CSIA) quality systems.

As a founding member of CSIA, we are committed to improving the business practices of controls and information system integrators. Re:Build Optimation has defined the quality processes for each service offered by a systems integrator, effectively coupling the advantages of an ISO 9001 quality system with the best practices of CSIA and process documentation.

We partner with Rockwell Automation to deliver best-in-class, turnkey automation and system integration solutions for our clients. Our team has decades of experience with the full suite of Rockwell products, including Allen-Bradley®, PlantPAx®, PanelView®, FactoryTalk®, and more.

As a company consistently honored as a Rochester’s Top Workplace, we take immense pride in our dedication to creating a thriving and inclusive environment for our team. Our ongoing commitment to employee development and satisfaction fuels our success and makes our workplace a truly exceptional place to grow and excel.

Ready to scale or optimize your operations? Our engineers are here to discuss your goals and map out the right solution.